-

Your solutionsYour solutions

Startpage

- Industries

-

Applications

-

Automation & Systems

Your solutions

-

Lithium-ion technology

Lithium-ion technology

Your solutions

-

Digitalisation and connectivity

Your solutions

-

Case studies

Your solutions

-

ProductsProducts

Startpage

-

New Forklifts

New Forklifts

Products

-

Forklift hire

Forklift hire

Products

-

Used Forklifts

Products

- Automated components

-

Batteries/charging technology

Batteries/charging technology

Products

- Warehouse Racking and Storage

- Special Builds

- Industrial IT

-

Operating manuals

Products

-

Jungheinrich efficiency is just round the corner.

Products

-

New Forklifts

-

Automation & SystemsAutomation & Systems

Startpage

-

Consulting warehouse optimization

Automation & Systems

- Mobile Robots

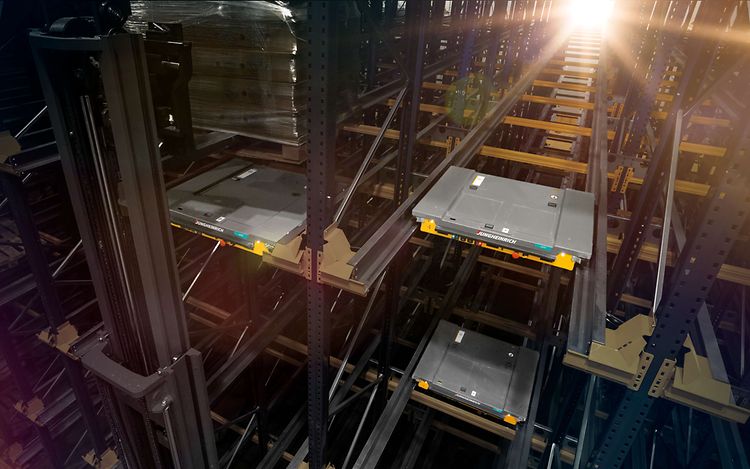

- Automated pallet warehouse

-

Automated miniload warehouse

Automated miniload warehouse

Automation & Systems

-

Jungheinrich PowerCube

Automation & Systems

-

Storage systems

- Digital products and software solutions

-

Consulting warehouse optimization

-

ServicesServices

Startpage

-

About usAbout us

Startpage

- Stories

-

Careers

About us

-

Press/events

About us

- Innovation & Aspiration

-

Certificates/policies

About us

-

Regional Locations

About us

-

ShopShop

Startpage

-

Pallet trucks

Shop

-

Electric pallet trucks

Shop

-

Electric stacker trucks

Shop

-

Transport trolleys

Shop

-

Racks

Shop

-

Workplace equipment

Shop

-

Cabinets and drawers

Shop

-

Pallet trucks